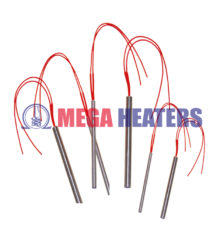

Cartridge Heaters

Showing 1–12 of 59 results

-

cartridge heater 4x200x230vx200w

Quick ViewA cartridge heater is a tube-shaped, heavy-duty, industrial element used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application. Compact designs are capable of reaching a watt density of up to 50W/cm² while some specialty high-temperature designs can reach 100w/cm².

Cartridge heaters are found useful in many applications, such as:

- Seal bars

- Torpedo heaters for injection molding

- Injection molding manifolds

- Mass spectrometry

- Rubber molding

- Food production

- Immersion tank heating

- HVAC compressors

- Fuel cells

- Semiconductors

- Medical devices

- Sensor measurement devices

- Extrusion

- Die casting

- Hot melt adhesives

- Heat staking/hole punch

- Plastic welding

- Fluid heating

- 3DPrinters

The sheath is the part of the cartridge heater which makes contact with the material or substance to be heated. Several metal alloys are used, depending on the type of application, such as highly acidic or corrosive environments. The most common types of sheaths are 304 stainless steel, 316 stainless steel, and Incoloy 800. Incoloy has the highest temperature rating and is considered a super rolly.

-

cartridge heater 6X110X200VX200W

Quick ViewA cartridge heater is a tube-shaped, heavy-duty, industrial element used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application. Compact designs are capable of reaching a watt density of up to 50W/cm² while some specialty high-temperature designs can reach 100w/cm².

Cartridge heaters are found useful in many applications, such as:

- Seal bars

- Torpedo heaters for injection molding

- Injection molding manifolds

- Mass spectrometry

- Rubber molding

- Food production

- Immersion tank heating

- HVAC compressors

- Fuel cells

- Semiconductors

- Medical devices

- Sensor measurement devices

- Extrusion

- Die casting

- Hot melt adhesives

- Heat staking/hole punch

- Plastic welding

- Fluid heating

- 3DPrinters

The sheath is the part of the cartridge heater which makes contact with the material or substance to be heated. Several metal alloys are used, depending on the type of application, such as highly acidic or corrosive environments. The most common types of sheaths are 304 stainless steel, 316 stainless steel, and Incoloy 800. Incoloy has the highest temperature rating and is considered a super rolly.

-

cartridge heater 6x40x220vx100w

Quick ViewA cartridge heater is a tube-shaped, heavy-duty, industrial element used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application. Compact designs are capable of reaching a watt density of up to 50W/cm² while some specialty high-temperature designs can reach 100w/cm².

Cartridge heaters are found useful in many applications, such as:

- Seal bars

- Torpedo heaters for injection molding

- Injection molding manifolds

- Mass spectrometry

- Rubber molding

- Food production

- Immersion tank heating

- HVAC compressors

- Fuel cells

- Semiconductors

- Medical devices

- Sensor measurement devices

- Extrusion

- Die casting

- Hot melt adhesives

- Heat staking/hole punch

- Plastic welding

- Fluid heating

- 3DPrinters

The sheath is the part of the cartridge heater which makes contact with the material or substance to be heated. Several metal alloys are used, depending on the type of application, such as highly acidic or corrosive environments. The most common types of sheaths are 304 stainless steel, 316 stainless steel, and Incoloy 800. Incoloy has the highest temperature rating and is considered a super rolly.

-

cartridge heater 6x60x240vx180w

Quick ViewA cartridge heater is a tube-shaped, heavy-duty, industrial element used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application. Compact designs are capable of reaching a watt density of up to 50W/cm² while some specialty high-temperature designs can reach 100w/cm².

Cartridge heaters are found useful in many applications, such as:

- Seal bars

- Torpedo heaters for injection molding

- Injection molding manifolds

- Mass spectrometry

- Rubber molding

- Food production

- Immersion tank heating

- HVAC compressors

- Fuel cells

- Semiconductors

- Medical devices

- Sensor measurement devices

- Extrusion

- Die casting

- Hot melt adhesives

- Heat staking/hole punch

- Plastic welding

- Fluid heating

- 3DPrinters

The sheath is the part of the cartridge heater which makes contact with the material or substance to be heated. Several metal alloys are used, depending on the type of application, such as highly acidic or corrosive environments. The most common types of sheaths are 304 stainless steel, 316 stainless steel, and Incoloy 800. Incoloy has the highest temperature rating and is considered a super rolly.

-

cartridge heater 6x80x36vx100w

Quick ViewA cartridge heater is a tube-shaped, heavy-duty, industrial element used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application. Compact designs are capable of reaching a watt density of up to 50W/cm² while some specialty high-temperature designs can reach 100w/cm².

Cartridge heaters are found useful in many applications, such as:

- Seal bars

- Torpedo heaters for injection molding

- Injection molding manifolds

- Mass spectrometry

- Rubber molding

- Food production

- Immersion tank heating

- HVAC compressors

- Fuel cells

- Semiconductors

- Medical devices

- Sensor measurement devices

- Extrusion

- Die casting

- Hot melt adhesives

- Heat staking/hole punch

- Plastic welding

- Fluid heating

- 3DPrinters

The sheath is the part of the cartridge heater which makes contact with the material or substance to be heated. Several metal alloys are used, depending on the type of application, such as highly acidic or corrosive environments. The most common types of sheaths are 304 stainless steel, 316 stainless steel, and Incoloy 800. Incoloy has the highest temperature rating and is considered a super rolly.